Under the current situation of chip shortage and chaos in the industry market, overcoming chip technology problems, shaping brand image, and safeguarding intellectual property rights have become key points that we cannot ignore. The laser marking machine has obvious advantages for product marking, it is the preferred tool for processing marking in the chip industry.

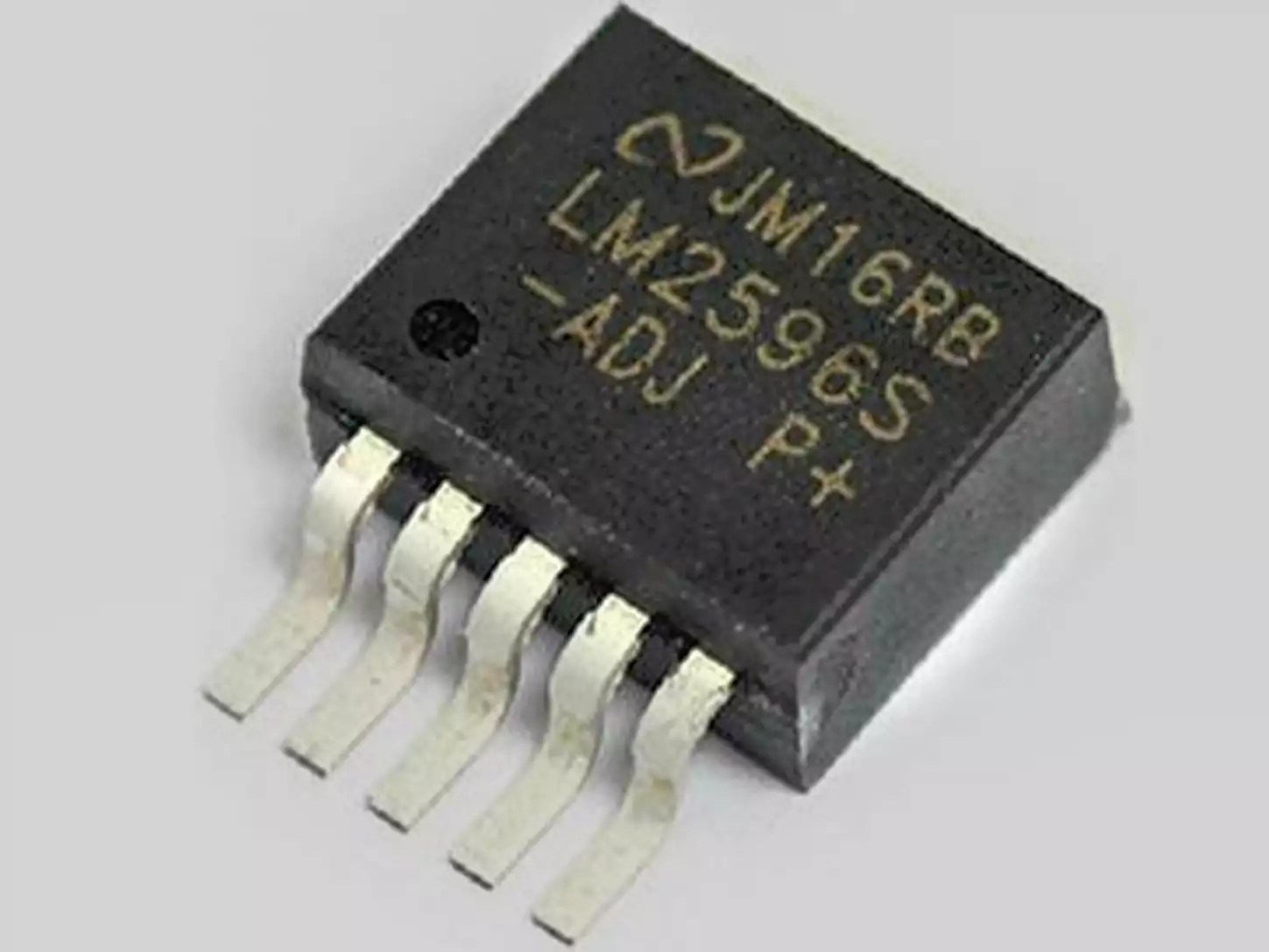

IC Chip laser marking machine can mark permanent characters of about 0.5mm in size and corporate logo patterns on the surface of the IC chip for product identification and tracking and corporate publicity.Mactron IC chip laser marking machine can mark clear text, model, manufacturer and other information without damaging the functional properties of the chip.

The IC Chip laser marking machine has imported high-precision CCD camera positioning and large-scale graphic visual recognition system, which can not only automatically locate products for marking and automatic detection of defective products, but also realize large-scale visual positioning and marking through the moving platform.

Advantages of IC laser marking machine:

1、Fully Automatic Integrated Design

2、Convenient Replacement Function

3、Process 12000PCS per hour, super fast speed

Compared with other laser marking machines, MACTRON IC chip laser marking machine can process a variety of different types of carrier chips. We only need to quickly adjust in the software interface to achieve multiple uses.

4、Suitable for 8-30mm different models

5、High-quality visual positioning system

Since the IC chip laser marking machine is loaded with a visual positioning system and automatic uncovering and laminating, we can realize automatic processing, which greatly improves production efficiency; the fault alarm system also further ensures the quality of the chip .

6、Sensitive foolproof and fault alarm system

7、Automatically complete the feeding, discharging, uncovering and laminating

If you want to know more about IC chip laser marking machine, you can click the link below

1、IC Chip Laser Marking Machine

2、Automatic IC Laser Marking Machine

IC Chip laser marking machine is widely used in electronic components, communications, automobile and motorcycle spare parts, etc. This model is mainly suitable for IC card marking, which can be marked with digital coding, LOGO, serial number, etc. The marking content is clear and permanent.

In order to better protect the chip from damage and deformation, conventional chip packaging methods include TAPE&REEL, TRAY, and TUBE. At present, Mactron has launched a variety of laser processing solutions. Customers can choose and customize laser marking equipment according to their own production lines requirements.If you are interested in the IC Chip laser marking machine, you can contact +86-15818389161.